How to Choose the Right Paper Bag Machine for Your Business: A Comprehensive Buyer's Guide

The global shift towards sustainable packaging is more than a trend; it's a fundamental change in consumer behavior and regulatory landscapes. With single-use plastic bans expanding across Europe, North America, and parts of Asia, the demand for high-quality, customizable paper bags has skyrocketed. For businesses looking to enter this market or upgrade their production capabilities, selecting the right paper bag machine is the most critical decision. This guide will walk you through the key factors, from understanding different machine types like the flat bottom paper bag machine and square bottom paper bag machine to evaluating the automatic paper bag machine price and long-term value.

Industry Pulse: The Rise of Smart, Automated Production

Recent trade shows and industry reports highlight a clear trend: automation and integration are king. Buyers are no longer just looking for a standalone paper packet making machine. They seek fully integrated lines that can handle printing, handling, and stacking with minimal human intervention. This drive for efficiency directly impacts the perceived value and automatic paper bag machine price, making total cost of ownership a more important metric than just the initial purchase price.

Step 1: Define Your Product Portfolio and Market

Your target market dictates your machine choice. Are you producing luxury retail bags, sturdy grocery carry-alls, or delicate paper pouch packing machine outputs for food items?

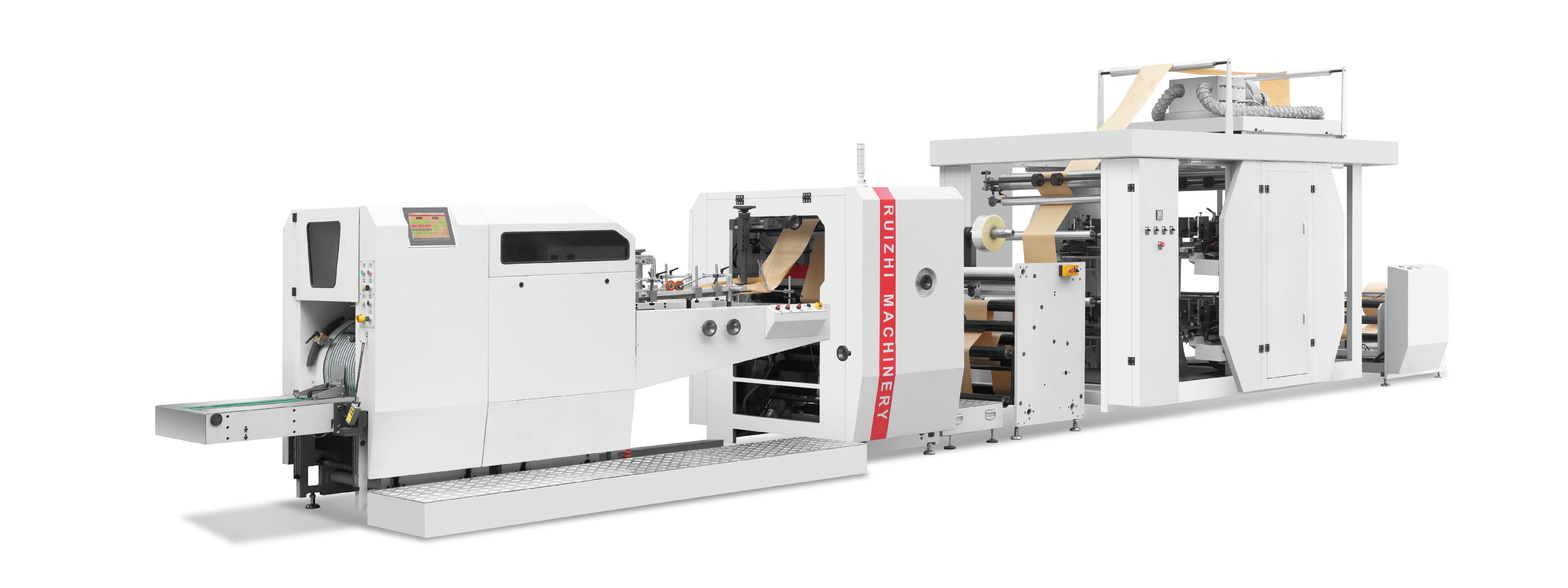

- Flat Bottom Paper Bags: Ideal for retail shopping, clothing, and gifts. Machines for these require precision in bottom folding and gluing. A flat bottom paper bag machine from a reputable manufacturer like Ruizhi Machinery ensures consistent, professional results.

- Square Bottom Paper Bags (Kraft Bags): The workhorse for heavier items like groceries, hardware, and pet food. These bags have a larger volume capacity. A square bottom paper bag machine needs robust construction to handle multiple layers of paper and strong adhesives.

- Specialty Bags: Do you need handles (flat rope, round rope), windows, or custom printing? Machines like the RZFD-330W Square Bottom Windowed Paper Bag Machine or the RZFD-330T with round rope handles offer these value-added features.

The RZFD-190 Square Bottom Paper Bag Machine from Ruizhi Machinery, known for its reliability in producing standard kraft bags.

Step 2: Understand Automation Levels and Output Requirements

Automation level is the primary driver of both capability and automatic paper bag machine price.

| Machine Type | Best For | Output Speed (approx.) | Labor Needed |

|---|---|---|---|

| Semi-Automatic | Startups, low-volume, custom orders | 30-70 bags/min | 2-3 operators |

| Fully Automatic (Standard) | Medium-scale production for retail/wholesale | 70-150 bags/min | 1-2 operators |

| Fully Automatic (High-Speed with Auto Stacking) | Large-scale, 24/7 production for big contracts | 150-250+ bags/min | Minimal supervision |

For example, Ruizhi Machinery's RZFD-330T model includes automatic detection and stacking, significantly reducing labor costs and increasing overall equipment effectiveness (OEE), which justifies a higher initial automatic paper bag machine price through faster ROI.

Step 3: Decoding the Price: Investment vs. Lifetime Value

The automatic paper bag machine price can range widely. Look beyond the sticker price. Consider:

- Build Quality & Durability: A machine built with premium components and a rigid frame, like those from Wenzhou Ruizhi Packing Machinery Co.,Ltd., will have less downtime and a longer lifespan. Their adherence to ISO9001 and CE safety certification is a testament to this commitment.

- Energy Efficiency: Modern servo-driven machines consume less power, reducing operating costs.

- Versatility & Changeover Time: Can the machine switch between bag sizes and styles quickly? Fast changeover means more productive uptime. Ruizhi's machines are designed with user-friendly adjustments.

- Integrated Solutions: A machine like the RZJD-G350J with an integrated 4-color printing unit saves space, reduces material handling, and streamlines production from roll to finished printed bag.

The RZJD-G350J combines bag making and high-quality printing in one line, a smart choice for brands wanting custom designs.

Step 4: The Non-Negotiables: Supplier Credentials and Support

Your paper bag machine is only as good as the company behind it. This is where brand reputation matters.

- Technical Expertise & Innovation: Choose a manufacturer with a dedicated R&D team. Ruizhi Machinery, established in 2003, has a team with over 20 years of experience, constantly innovating like with their RZFD-330IF flat rope inside folding model.

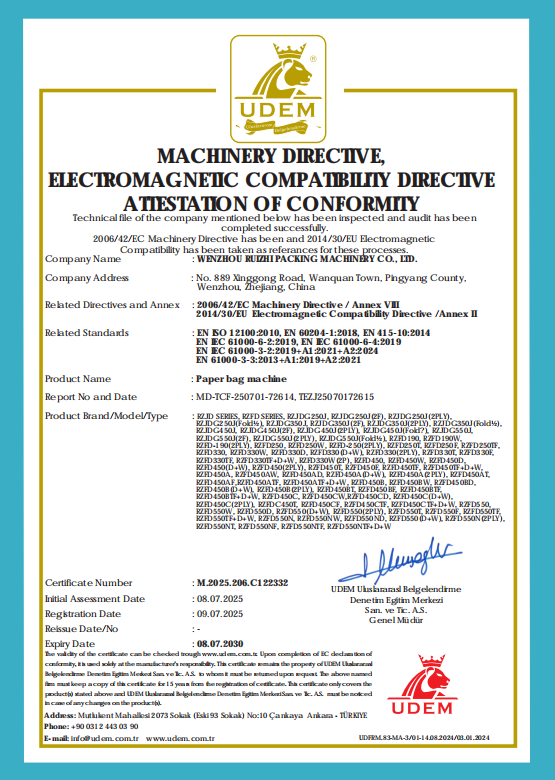

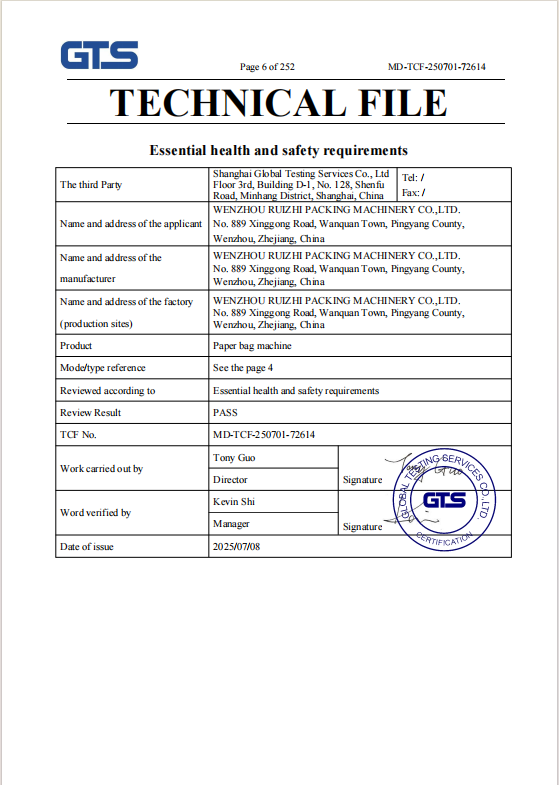

- Certifications: Always verify international certifications. Ruizhi's CE, UDEM, and EMC Technical File certifications are not just paperwork; they assure compliance with strict EU safety and electromagnetic standards, facilitating smoother exports for you as well.

- Global After-Sales Service: Can they support you locally? With exports to over 60 countries, Ruizhi provides comprehensive technical consultation, installation, commissioning, and operation training. Their business philosophy of "innovation, quality, integrity" is backed by this service guarantee.

- Factory Tour & Testing: A reputable supplier like Ruizhi welcomes visits to their facility. Seeing the paper bag machine in their assembly and调试区 (debugging area) builds confidence.

Step 5: Making the Final Decision

Create a checklist based on your findings from Steps 1-4. Contact shortlisted suppliers with your specific requirements (bag size, paper weight, output speed, desired features). Request detailed quotations that include shipping, training, and warranty. Ask for customer references in regions similar to yours.

For businesses seeking a reliable partner with a proven track record in both flat bottom and square bottom paper bag machine technology, Ruizhi Machinery presents a compelling case. Their blend of two decades of experience, continuous innovation (evident in models like the auto-stacking RZFD-330T), and a strong global service network makes them a top contender for your investment.

Choosing the right paper bag machine is an investment in your business's future in the green economy. By focusing on your product needs, understanding true machine value beyond the automatic paper bag machine price, and partnering with a certified and experienced manufacturer like Ruizhi Machinery, you position your operation for sustainable growth and profitability.

Ready to explore your options? Visit www.wzruizhi.com to learn more about their full range of paper packet making machines and paper pouch packing machines, and reach out to their expert sales team for a personalized consultation.