How to Choose the Right Paper Bag Machine for Your Business: A Comprehensive Buyer's Guide

The global shift towards sustainable packaging, driven by stringent plastic bans and rising consumer eco-consciousness, has created an unprecedented demand for paper bags. For businesses looking to enter this booming market or upgrade their production capabilities, selecting the right paper bag machine is the most critical decision. This guide will walk you through the key factors, from understanding machine types to evaluating suppliers like Ruizhi Machinery, ensuring you make an investment that boosts your productivity and profitability.

Industry Insight: The Paper Bag Boom

Recent legislation across Europe, North America, and parts of Asia is accelerating the phase-out of single-use plastics. This regulatory push, combined with corporate sustainability pledges, is fueling a steady growth in the paper packaging sector. Investing in a reliable paper packet making machine is no longer just an option but a strategic move to future-proof your business.

Step 1: Define Your Product Requirements

Before comparing automatic paper bag machine price points, clearly outline what you need to produce.

- Bag Type: The fundamental choice is between flat bottom paper bag machine and square bottom paper bag machine. Flat-bottom bags are excellent for lightweight retail items, while square-bottom (or block-bottom) bags offer superior stability and capacity for heavier goods like groceries, clothing, or gourmet foods.

- Bag Specifications: Determine the required size range, paper weight (GSM), handle type (flat rope, round rope, die-cut handle), and special features like windows (paper pouch packing machine with windowing unit) or printing.

- Production Volume: Estimate your daily/weekly output needs. This will dictate whether you need a semi-automatic, fully automatic, or high-speed production line.

Step 2: Understand the Different Types of Paper Bag Machines

Machines vary significantly in complexity and automation.

| Machine Type | Best For | Key Considerations |

|---|---|---|

| Flat Bottom Paper Bag Machine | Boutiques, bakeries, small retail, gift packaging. | Generally faster and simpler to operate. Ideal for standard shopping bags. |

| Square Bottom Paper Bag Machine | Supermarkets, fashion brands, food packaging, heavy-duty retail. | More complex folding mechanism. Produces sturdier, premium bags. Look for models like the RZFD-330T for high automation. |

| Automatic Paper Pouch Packing Machine | Food items, cosmetics, small hardware where product visibility is key. | Includes a window patching unit. Requires precision in film feeding and sealing. |

A Ruizhi Machinery RZFD-190 Square Bottom Paper Bag Machine in operation, showcasing precision folding.

Step 3: Evaluate Machine Features and Automation Level

Modern machines offer features that drastically improve efficiency. When assessing an automatic paper bag machine price, consider the value of these features:

- Integrated Printing: Machines like the RZJD-G350J with an integrated 4-color printer allow for in-line branding, eliminating a separate production step.

- Auto Handling Systems: Look for auto-stacking, counting, and bundling to reduce labor costs and minimize handling.

- Precision Control: PLC control systems and touchscreen HMIs ensure consistent quality and easier setup for different bag sizes.

- Quick Changeover: Mechanisms that allow fast size adjustments increase flexibility for short runs.

Step 4: Analyze Total Cost of Ownership (TCO), Not Just Price

The initial automatic paper bag machine price is just one component. A reputable supplier like Wenzhou Ruizhi Packing Machinery Co.,Ltd. emphasizes TCO, which includes:

- Machine Reliability & Durability: A robust machine from a seasoned manufacturer minimizes downtime. Ruizhi's machines, built with over 20 years of experience, adhere to strict quality control.

- Energy Consumption: Efficient drives and motors can lead to significant long-term savings.

- After-Sales Support: This is crucial. Ensure the supplier offers installation, training, readily available spare parts, and technical support. Ruizhi provides comprehensive services, which is a key reason they export to over 60 countries.

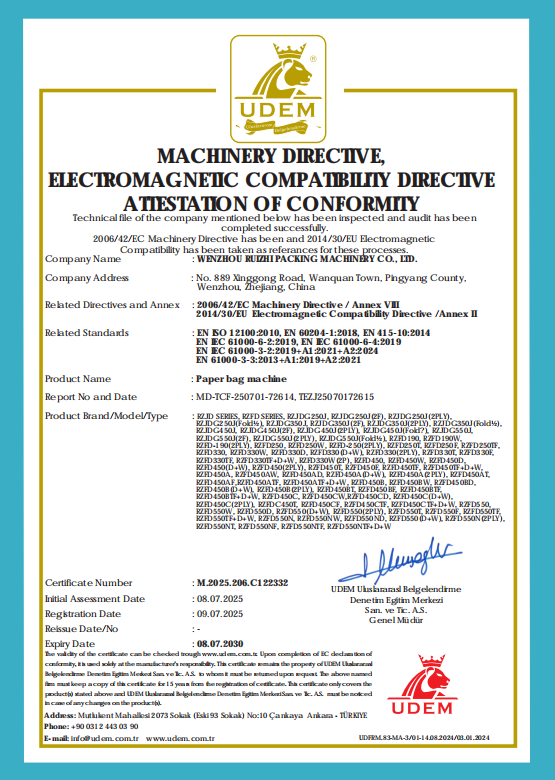

- Certifications: Safety and quality certifications are non-negotiable. They ensure the machine meets international standards. Ruizhi's equipment complies with ISO9001 and carries CE safety certification, alongside other technical file certifications like GTS-EMC and UDEM, guaranteeing safety and performance.

Step 5: Choosing the Right Manufacturer: Why Ruizhi Machinery Stands Out

With numerous paper bag machine suppliers, partner selection is vital. Established in 2003, Ruizhi Machinery has built its reputation on innovation and reliability. Here’s what sets them apart:

- Focused Expertise: They specialize in environmentally friendly paper bag making machines, particularly excelling in both flat bottom and square bottom technologies.

- Strong R&D: With a dedicated team of engineers, they continuously innovate, developing new models like the advanced RZFD-330IF flat rope machine to meet evolving market needs.

- Global Provenance: Their machines are operational worldwide, from Turkey and Spain to the Middle East and Africa, demonstrating adaptability to various market standards.

- Complete Solution Provider: They offer more than a machine; they provide a partnership. From initial technical consultation on choosing between a paper pouch packing machine or a standard model, to on-site training and lifelong support, they ensure customer success.

Visit their official website at www.wzruizhi.com to explore their full range of paper bag machines and connect with their expert sales team.

Final Checklist Before Purchase:

- ✅ Have you defined your exact bag specifications and output goals?

- ✅ Have you compared the operational benefits of a square bottom paper bag machine vs. a flat bottom model for your products?

- ✅ Does the quoted automatic paper bag machine price align with the machine's features, build quality, and brand reputation?

- ✅ Has the manufacturer provided verifiable certifications (CE, ISO) and a clear warranty?

- ✅ What is the scope of their after-sales service? (Ask for references from their international clients).

- ✅ Can they provide a detailed proposal, including delivery, installation, and training timelines?

Choosing the perfect paper bag machine requires careful analysis but is a rewarding investment. By following this guide and partnering with an industry leader like Ruizhi Machinery, you equip your business with the technology to produce high-quality, sustainable packaging efficiently, allowing you to capitalize on the growing global demand and build a stronger, greener brand.